Photos and Article by Mary Alice Murphy

Silver City-Grant County Chamber of Commerce members tour Syzygy Tile

Silver City-Grant County Chamber of Commerce members tour Syzygy Tile

The kilns used in firing Syzygy Tile's handmade tiles.

Silver City-Grant County Chamber of Commerce members tour Syzygy Tile

Small tiles.

Silver City-Grant County Chamber of Commerce members tour Syzygy Tile

Showroom Manager Patrick Hoskins shows off the storage of glazes

Silver City-Grant County Chamber of Commerce members tour Syzygy Tile

Brushes for glazing tiles

Silver City-Grant County Chamber of Commerce members tour Syzygy Tile

The racks that go into the kilns.

Silver City-Grant County Chamber of Commerce members tour Syzygy Tile

This glaze is called midnight, because it creates a very dark blue after the tile is fired.

Silver City-Grant County Chamber of Commerce members tour Syzygy Tile

And this glaze give a purple-blue

Silver City-Grant County Chamber of Commerce members tour Syzygy Tile

A tile before firing.

Silver City-Grant County Chamber of Commerce members tour Syzygy Tile

What it might look like after firing.

Silver City-Grant County Chamber of Commerce members tour Syzygy Tile

A fireplace surround custom-made for a California designer.

Silver City-Grant County Chamber of Commerce members tour Syzygy Tile

Syzygy Tile co-owner David DelJunco works on a mold.

Silver City-Grant County Chamber of Commerce members tour Syzygy Tile

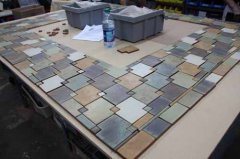

Syzygy samples for a showroom.

Members of the Silver City-Grant County Chamber of Commerce toured Syzygy Tile during their monthly luncheon on Thursday, Oct. 1.

Owner Lee Gruber welcomed the group and apologized because she had to leave for Las Cruces for a Tourism Meeting. Her husband, David DelJunco, was also there, but he quietly made molds in the factory part of the tile manufacturing facility.

Announcements at the beginning of the meeting reminded people of the Pinos Altos October Fiesta, which takes place this Saturday, Oct. 3, from 10 a.m. to 4 p.m. as a fundraiser for the Pinos Altos Volunteer Fire and Rescue. Sandy Feutz of the Grant County Art Guild and the Silver City Art Association announced events taking place at the Pinos Altos Hearst Gallery this weekend and the Red Dot Weekends on Oct 10-12 and Oct. 16 and 17, in Silver City and at the gallery in Pinos Altos.

Chamber Board president Tony Trujillo said the board, at its meeting Thursday morning, had decided to bring back the Chamber Community Awards, which will take place Nov. 19.

Syzygy Tile Showroom Manager Patrick Hoskins gave a brief history of the facility. "When Lee and David began, they were not schooled in ceramics, but they became intrigued with it after visiting another small tile factory. They bought a kiln and a book and starting experimenting in their garage. They spent two years developing the science and refining the art of tile-making."

He said they made the decision to place their factory downtown and had been in the location for 22 years.

"Lee drove around the country with tiles in her trunk," Hoskins said. "That's how they marketed. Now they are in 140 showrooms across the country. It's undeniably a labor of love. Twenty of us work here. I have the easy part—talking about what we do. Not everything in the showroom is ours, because we have tiles from other small outfits, too.

"It's all about art for your home," Hoskins continued. "Handmade is what it's about here. This company stands behind what they do. We want to import some of our passion."

In the factory part of the facility, he pointed out the 11 kilns, which fire at 17,000 watts each. "With PNM's help, we lowered our electricity bill by shifting when we run the kilns to the nighttime."

Hoskins explained the company has a specific formula in order to make consistent tiles. "We shape the clay three ways. One is field tile. You take this block of damp clay and throw it to flatten it, and then run it through the slab roller for uniform thickness. Next we use a cookie cutter approach and cut out shapes. We can decorate the field tile with any kind of sculpted motif. We make our own molds. Hand presses make one tile at a time. There are no shortcuts to what we do. That's why our product is pricy."

He pointed out the extruder barrels, which make a long bar of a certain shape and then it is cut into pieces.

The only automated machine in the place, most being manually operated, was the machine that grinds the scraps. "We feed the small bits into the machine and it grinds them up. It also gets rid of all the air bubbles, which could make a tile explode in the kiln. Out of the ground up clay, we create solid blocks that we can work with again."

"Almost everyone who works here is trained here," Hoskins said. "If they come with training, they have to unlearn it."

He pointed out the washer and dryer, because the Laundromat had kicked them out because the clay stained their machines.

"Lee and David chose a red body clay, because it spoke to the history of the area," Hoskins said. "It is made by a commercial manufacturer, because we don't have a sufficient supply here."

He pointed out one artist who was putting a glaze onto a tile and then removing it carefully, so it left just a bit of color. He noted that learning how to glaze could take a year.

"It takes about a month to make a tile," Hoskins said.

Cynthia Bettison, Silver City mayor pro tem, complimented Hoskins for the cleanliness and order in the factory. Hoskins said that makes it more efficient because things can be found easily.

"We work with a lot of glazes," Hoskins said. "We use small batches. The glaze colors equally come from the actual ingredients and how we put them onto the tiles. You have to do it right the first time. A tile can have two to eight coats of glaze and two to four colors."

A lot of their production is for special orders. He pointed out a fireplace surround that had been requested by a designer in California. Each tile is numbered to make sure the puzzle fits together when it's time to install.

Editor's Note and recommendation: Next year, if you haven't had a chance to see the inside of the Syzygy system, take the tour during the 2016 Clay Festival.